AFM NEWS

Counting Trees with Purpose: Inside a Timber Inventory Project

In some businesses, counting inventory means literally counting or scanning thousands upon thousands of items. In forestry, this would be quite a daunting task! Imagine a group of foresters lacing up their boots and trekking into the woods to count every tree spanning hundreds of acres! Not only would this be cumbersome, but it wouldn’t be utilizing the impressive technology available to inventory managers. A timber inventory is the process of estimating the amount, size, and species of standing trees on a property. It helps landowners and managers make informed decisions about forest health, value, and future management. Learn how inventory managers use timber inventory data to advise clients and the technology that makes it possible.

Timber inventories provide landowners and managers with crucial information about the landowner’s forest assets. Without this data, it’s impossible to make informed decisions that will align with the landowner’s objectives or guide silvicultural activities that ensure forest health and vigor. For instance, a landowner may be curious about what their timber is worth, and having this data informs next steps, like whether the trees should continue to grow, whether thinning should be performed, and more. Landowners may also wish to explore other avenues or revenue streams, including recreation or carbon projects. Now that we have covered the purpose of a timber inventory, let’s turn our focus to how one is conducted.

Step 1: Determine the Objectives and the Budget

In this example, our client wants to know the mean volume of the standing timber for their property with 95% confidence. An inventory design is then developed to meet the statistical criteria. The design may include stratification (dividing the property into similar forest types or conditions for more efficient sampling), a simple grid of plots across the property, or a more intensive stand-level inventory. The total number of plots is determined by applying a statistical sample size formula, which relies on past inventory experience.

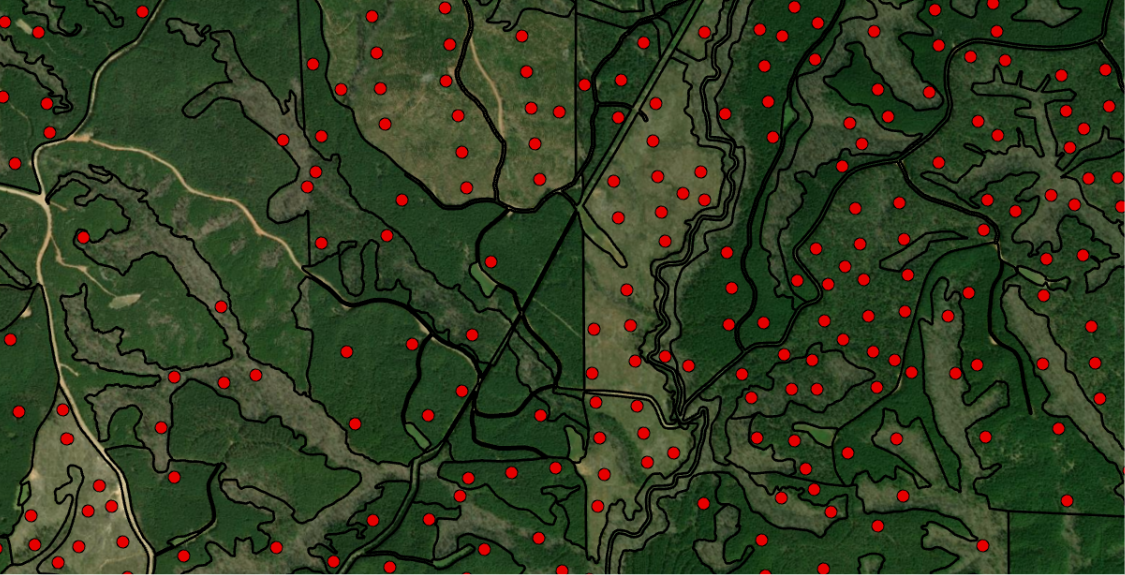

Step 2: Create a Grid

The property is overlaid with an evenly spaced grid using GIS, like a checkerboard or mesh. This design creates an even distribution of plots across all forest types and conditions, making it easier to calculate stand-level and property-wide estimates for forest metrics. Each intersection or center point of a grid cell becomes a plot location where foresters will collect inventory data (e.g., tree species, diameter, height, health).

Step 3: Cruise the Property

The gridded GIS layer in the last step helps foresters navigate to each plot in the field using GPS. Cruisers collect the data in the field based on established cruising protocols, like what information should be collected, how it is collected, and the merchandising specifications. For instance, foresters will determine diameter at breast height (DBH), the tree’s total height, merchantable height, species, defects, and insect/disease damage or issues.

Step 4: Merchandise the Tree Into Products

To merchandise a tree into products, in terms of an inventory, means to estimate the products each tree could be processed into at a mill. This is accomplished by evaluating the tree into its most valuable and appropriate commercial product categories based on its size, quality, and market demand. When a tree is harvested, it isn't just cut and sold as-is. Instead, each tree is assessed and divided into segments to be sold for specific uses, like sawtimber, pulpwood, chip-n-saw, veneer logs, or biomass.

Step 5: Create the Client Deliverable

Once all of the data is collected and merchandised into products, it is summarized for each plot. This data is statistically averaged, the confidence intervals are calculated, and the information is exported (sometimes in an Excel spreadsheet or similar style) for the client to consume.

Timing and Frequency: When to Inventory Your Timber

Although inventory can be conducted at any time of the year, the weather in certain regions around the country dictates timing. For instance, foresters in the Upper Peninsula of Michigan may need to dig through snow to measure DBH at 4.5 feet! In some cases, it is best to measure trees during the dormant season from late fall to early spring. Depending on the tree species and type of stand (planted versus natural), inventories are completed more frequently, such as after a stand thinning. Southeast planted stands of loblolly or slash pine may be inventoried every five years, while a natural stand in the Appalachians or Northern Hardwoods may be inventoried every 7-10 years. The former focuses on a product call for the entire tree, while the latter focuses on 8-16-foot-long logs. Both instances still record DBH, total, and merchantable heights, as well as species. Another point worth noting about the timing of an inventory project is that if the landowner is planning to buy or sell a property, their due diligence period should include an inventory to assess the asset they wish to buy or sell.

Tools of the Trade: From Clinometers to Remote Sensing

Lastly, several types of technology play a role in making a timber inventory come to fruition. The “old school” technology that has been the standard for over 100 years includes diameter tapes, clinometers (a handheld tool that measures tree heights from angles and triangulation), relascopes (another handheld tool that measures tree diameter, basal area, and heights), paper, pencils, and boot leather. More recent technology advancements include handheld data recorders (like tablets and phones) and laser and ultrasound devices to measure tree height and distances. Although these tools are less common, drones can collect aerial photos and estimate height and tree counts, and LiDAR from airplanes, drones, and backpacks can estimate tree height, crown size, tree counts, diameter, basal area, and volume. Handheld recorders coupled with GPS for data entry and navigation, combined with the use of lasers for distance and height, have been important incremental changes. Remote sensing data, whether free publicly available satellite data, pay-for-use daily satellite data, and LiDAR (aerial and terrestrial), have interrupted traditional inventory methods by providing more efficient methods to estimate inventory metrics. However, traditional inventory methods are still needed to calibrate and confirm the remote sensing methods.

Timber inventory is complex. Different forest types, budgets, and objectives for the same property require different inventory methods. Whether a landowner is evaluating timber value, preparing for a sale, or exploring new revenue streams like carbon, a reliable timber inventory lays the groundwork. It’s not just a snapshot of what’s standing, it’s the foundation for everything that comes next.